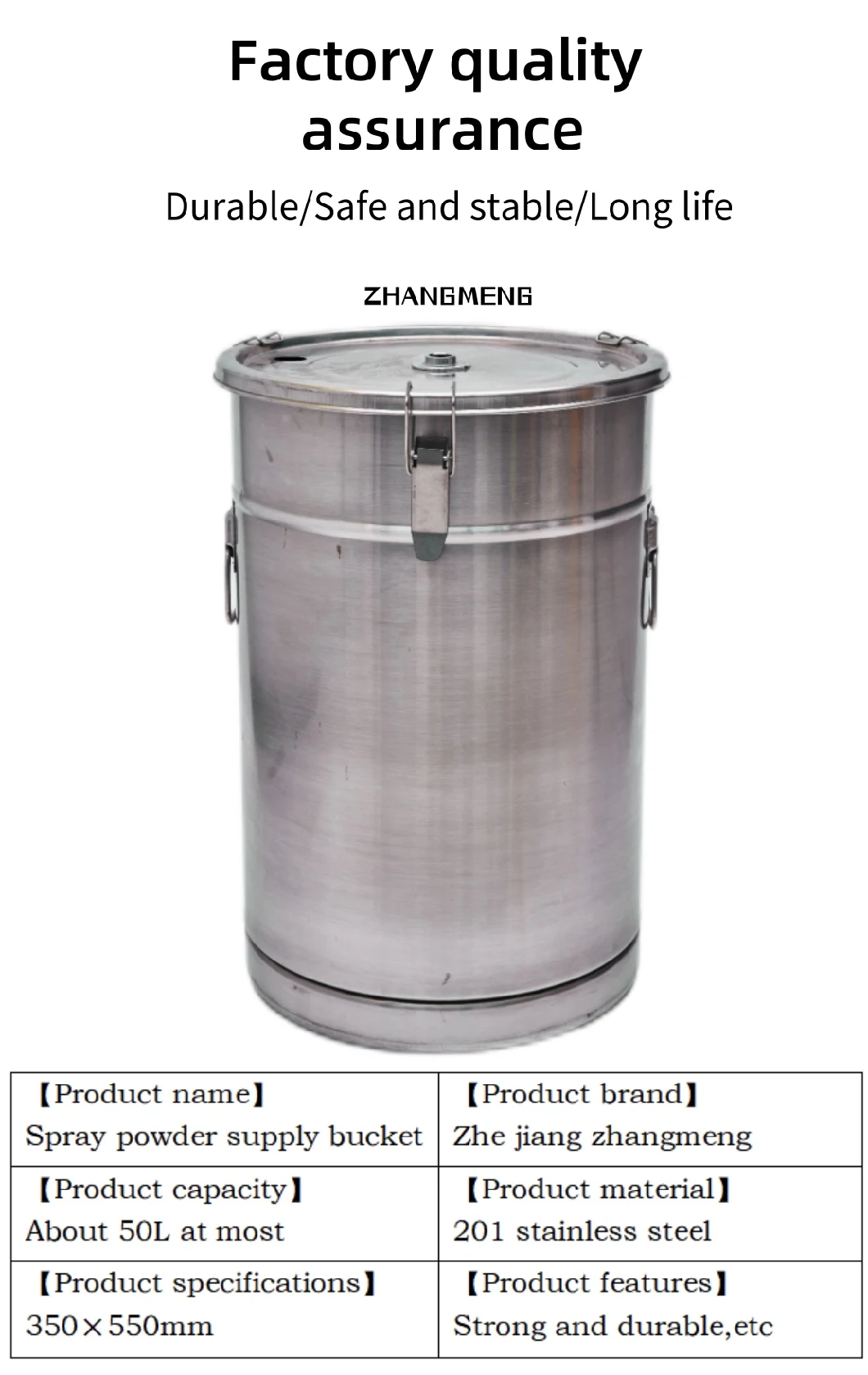

Protective Treatment of Table Surface Special Stainless Steel Pigment Powder Hopper Container for Spraying Powder Spraying Machine

1. Company introduction: Our company is a professional manufacturer of automatic spraying equipment, mainly producing au

Basic Info

| Model NO. | ZM-808 |

| Method Type | Automatic |

| Condition | New |

| Use for | Powder Coating Machine |

| Material | Stainless Steel |

| Colour | Silvery |

| Shape | Circular |

| Packing | Carton |

| Transport Package | Carton |

| Specification | Width 37 cm, height 54.5 cm |

| Trademark | Zhangmeng |

| Origin | Zhejiang, China |

| HS Code | 8424909000 |

| Production Capacity | 3000set/Year |

Product Description

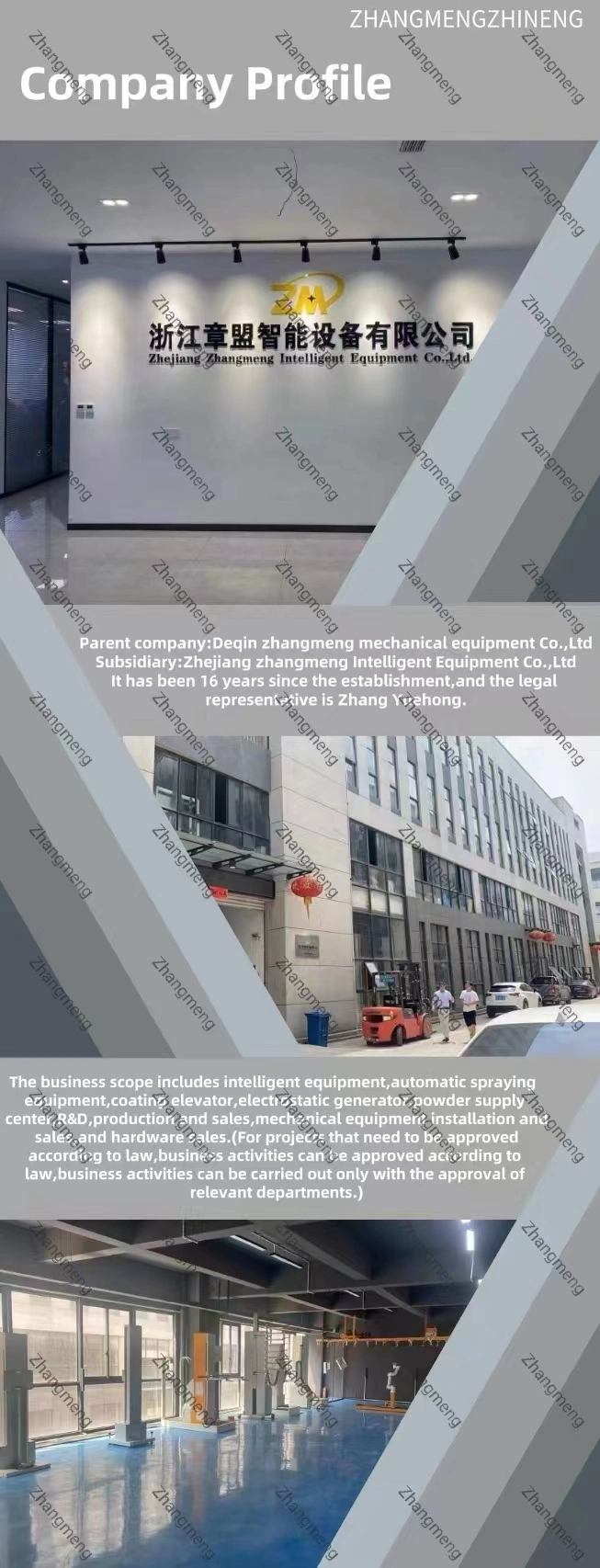

1. Company introduction:Our company is a professional manufacturer of automatic spraying equipment, mainly producing automatic spraying equipment, mechanical automation instead of traditional manual spraying, there has been the formation of mass production of reciprocating machines, spray guns, robots, etc., but also according to the requirements of custom non-standard automated machinery, assembly line, etc., our company has been established for 16 years, involving various fields, there are a large number of successful case study video can be drawn on.2. Product introduction:

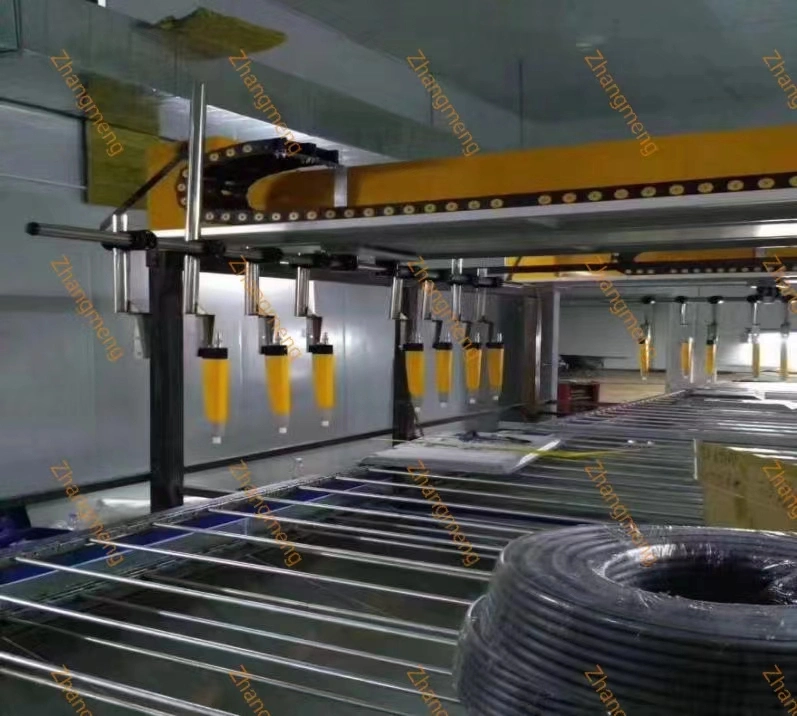

Principle: The positive and negative poles attract each other. The workpiece being sprayed is the positive pole, and the gun is the negative pole. There is a discharge needle at the outlet of the gun. The negative high voltage generated in the gun will produce a corona discharge phenomenon through the discharge needle. Under the action of electrostatic and compressed air, the sprayed negatively charged powder microparticles reach the surface of the workpiece and attract each other through electrostatic, so that the powder is evenly adsorbed on the surface of the workpiece and does not fall off.

Advantages:

(1)Large powder output and high static electricity.

(2)Adjustable current and voltage. You can adjust the current and voltage according to the effect of spraying.

(3)Traditional model, practical, good not expensive.

| 1 | Maximum working voltage | 70-100kV |

| 2 | Normal working current | 30-70μA |

| 3 | Protection current | 150μA |

| 4 | Continuous working time | more than 8 hours |

| 5 | Voltage of machine module | 21V |

Our company's annual production is more than 3000 sets, to provide services to customers around the world, has formed an assembly line mode of operation, in the pre-sale, sale, after-sales process have a complete set of processes, scale and system management to ensure that each customer purchase.Detailed Analysis:

(1) 16 years of business has delivered tens of thousands of sets of equipment around the world, how to ensure that after-sales? First of all, our company's products are modular components, each unit is an independent individual, quick unplug can be replaced, no need for home service, only the user can operate their own.

(2) We have a professional team, 24/7 guarantee one-on-one fast docking, feedback.(3)Packaging: As long as it is exported, we all use fumigated wood packaging to avoid damage.(4)Company scenes show: industry gatherings.(5) Visits from international friends.(6) Real feedback on warehouse inventory.

Send to us